ABSMaterial: A Guide to Its Uses and Benefits in 3D Printing

When it comes to selecting the right material for 3D printing, ABS (Acrylonitrile Butadiene Styrene) stands out as one of the most popular and versatile thermoplastics available. Known for its strength, durability, and heat resistance, ABS is a go-to material for a variety of applications, ranging from functional prototypes to final products.

In this guide, we’ll explore why ABS is such a popular choice in the 3D printing world, highlighting its key advantages and the types of projects it’s best suited for. Whether you’re just starting out or looking to transition to a more robust material, ABS offers several benefits that can help elevate your 3D printing projects.

What is ABS in 3D Printing?

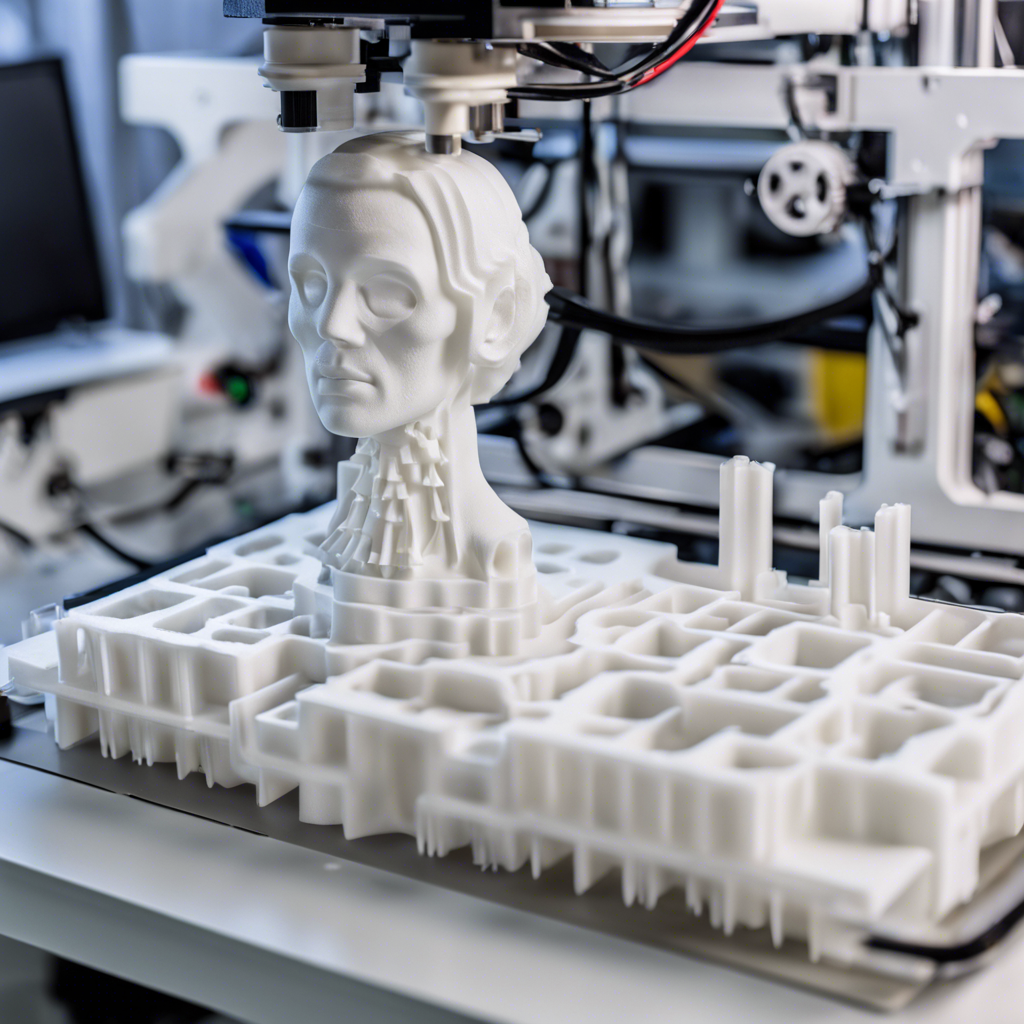

ABS is a petroleum-based plastic that is widely used in both injection molding and 3D printing. It’s the same material found in everyday items like LEGO bricks, automotive parts, and home appliance components. In 3D printing, ABS is primarily used in Fused Deposition Modeling (FDM) printers, where the filament is heated and extruded layer by layer to build the final object.

One of ABS’s most notable characteristics is its strength. It’s much tougher than PLA, making it a top choice for parts that need mechanical strength, impact resistance, and the ability to withstand higher temperatures.

Advantages of ABS for 3D Printing

-

Durability and Strength

ABS is highly durable, making it perfect for functional parts that need to endure mechanical stress. Its toughness allows it to absorb impacts and resist wear, making it ideal for parts that will experience frequent use. -

Heat Resistance

One of ABS’s standout qualities is its resistance to high temperatures. Unlike PLA, which can deform at lower temperatures, ABS can withstand heat without warping or losing its structural integrity, making it the preferred material for parts that need to operate in hot environments or endure repeated heating cycles. -

Flexibility and Mechanical Properties

ABS strikes a balance between rigidity and flexibility. It’s strong yet slightly flexible, making it ideal for parts that need to retain their shape while still offering some give under stress. This makes it great for moving parts, functional prototypes, and engineering components. -

Smooth Surface Finish

ABS can be post-processed to achieve a smooth, polished surface. It’s easy to sand, paint, or polish, and acetone vapor treatment can give ABS prints a professional, glossy finish, perfect for visually appealing products. -

Affordable and Accessible

Despite its robust properties, ABS is an affordable 3D printing material. It’s widely available and cost-effective, making it accessible for hobbyists, small businesses, and large-scale industrial users alike.

Challenges of Printing with ABS

While ABS offers numerous benefits, it does come with a few challenges:

- Warping: One of the most common issues with ABS is warping, where the edges of the print lift off the build platform. This happens because ABS contracts as it cools, leading to distortion. Using a heated bed (typically between 90°C to 110°C) can help minimize this issue.

- Odor and Fumes: ABS emits fumes during the printing process that can be unpleasant and harmful in poorly ventilated spaces. It’s recommended to print in a well-ventilated area or use an enclosure to manage the fumes.

- Print Bed Adhesion: Ensuring proper adhesion to the print bed can be tricky, especially for larger prints. Adhesion aids like kapton tape, glue, or a PEI sheet can help improve bed adhesion and prevent lifting.

Best Applications for ABS in 3D Printing

Thanks to its mechanical properties, ABS is ideal for a wide range of applications, from prototyping to end-use products:

-

Functional Prototypes

ABS is excellent for creating functional prototypes that require mechanical strength and durability. Its ability to handle impact and stress makes it ideal for testing and refining designs before moving to production. -

Automotive Parts

ABS is widely used in the automotive industry for parts like dashboards, panels, and mechanical components due to its ability to withstand heat, pressure, and wear. In 3D printing, ABS is commonly used for custom car parts and replacement components. -

Consumer Products

ABS’s strength and smooth surface make it a popular choice for producing consumer goods like toys, appliances, and gadgets. Its ease of post-processing (painting, polishing) makes it versatile for creating polished, end-use products. -

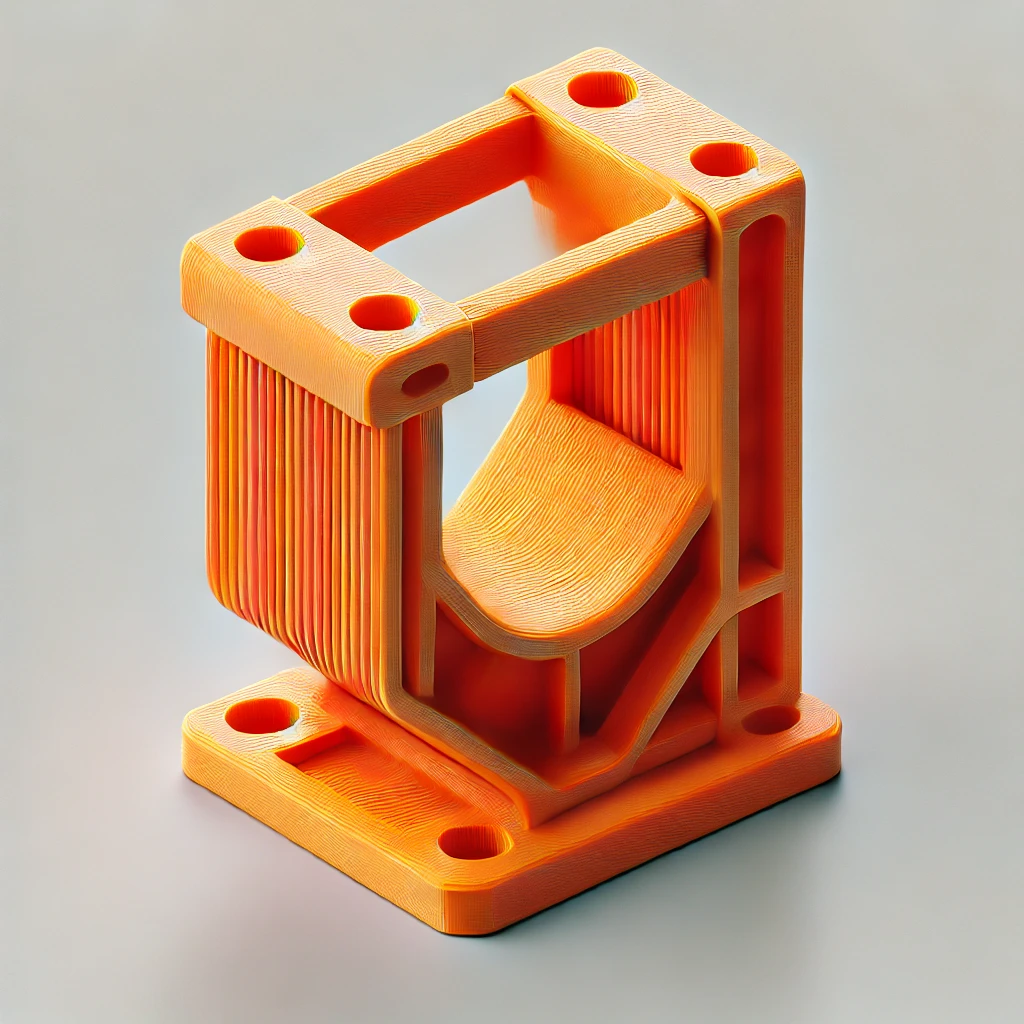

Engineering Components

ABS is often used in engineering and mechanical applications for moving parts, gears, and housings for machinery. Its strength, flexibility, and resistance to wear make it ideal for demanding engineering needs. -

Wearable Items

ABS’s rigidity and durability make it great for creating wearable items, such as phone cases, protective gear, and accessories. Its ability to maintain shape under stress and heat exposure ensures long-lasting performance.

How to Successfully Print with ABS

Printing with ABS requires a bit more preparation and care compared to materials like PLA. Here are some tips to ensure successful results:

- Heated Bed: ABS requires a heated bed between 90°C and 110°C to prevent warping. Using a fully enclosed 3D printer can help maintain a consistent temperature throughout the print.

- Print Speed: ABS performs best at speeds between 30mm/s and 60mm/s. Slowing down the print speed for larger or more complex prints can help prevent issues like layer separation.

- Temperature Settings: ABS typically extrudes at a temperature between 220°C and 250°C, depending on the filament and printer being used. Always follow the manufacturer’s recommendations for the filament you are using.

- Proper Ventilation: Ensure your printing space is well-ventilated or use an air filtration system to handle the fumes generated during the printing process.

Is ABS the Right Material for Your 3D Printing Needs?

Choosing the right material depends on the specific requirements of your project. If you need a strong, durable, and heat-resistant material that can withstand stress and impact, ABS is an excellent choice. Its versatility makes it suitable for a wide range of applications, from functional prototypes to end-use products.

At Monk 3D Technologies, we provide high-quality ABS filaments in various colors and diameters to suit your 3D printing needs. Whether you’re printing mechanical components, consumer products, or custom prototypes, ABS will deliver reliable, high-quality results.