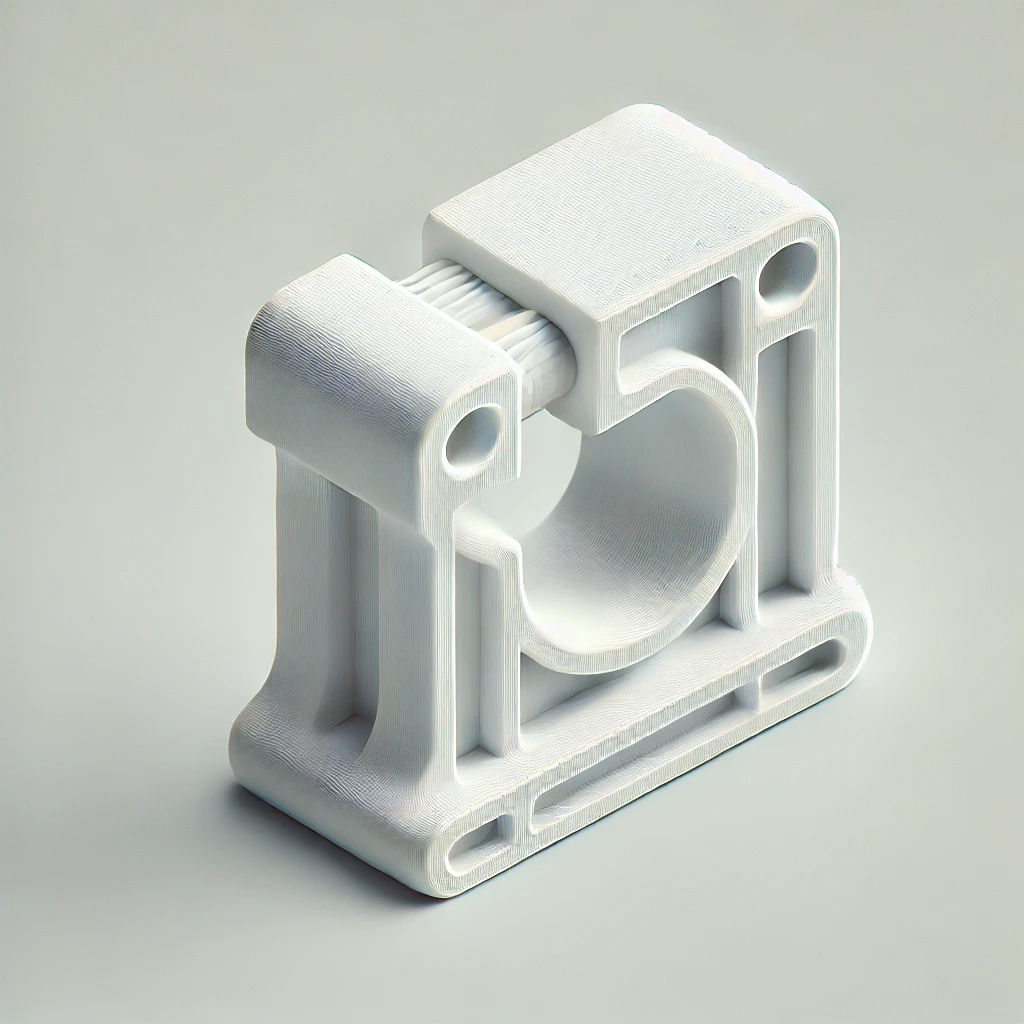

PETG Material for 3D Printing: The Perfect BalanceBetween Strength and Flexibility

If you’re diving into the world of 3D printing and looking for a material that strikes the perfect balance between strength, flexibility, and ease of use, PETG (Polyethylene Terephthalate Glycol) is an excellent choice. PETG combines the best features of two popular 3D printing materials: the strength of ABS and the flexibility and user-friendliness of PLA. In this blog, we’ll cover everything you need to know about PETG, its advantages, and why it could be the ideal material for your next 3D printing project.

What is PETG?

PETG is a modified version of PET, a widely used plastic found in water bottles and food packaging. The “G” in PETG stands for glycol, which is added during the polymerization process to enhance the material’s durability, flexibility, and ease of printing. PETG has become increasingly popular in the 3D printing community due to its unique blend of strength, durability, and flexibility. It also offers excellent resistance to chemicals, making it a great option for projects requiring a material that can endure tougher environmental conditions.

Advantages of PETG for 3D Printing

PETG is often considered the best of both worlds, offering the benefits of both PLA and ABS. Let’s take a look at the key advantages of using PETG for your 3D printing projects:- Strength and Durability PETG stands out for its impressive durability. It is stronger than PLA and almost as tough as ABS, making it ideal for parts that need to withstand mechanical stress and impact. Whether you’re producing functional prototypes, engineering components, or wearable items, PETG provides the strength needed for demanding applications.

- Flexibility Unlike ABS, which can be brittle, PETG offers a degree of flexibility, reducing the risk of cracking under pressure. This makes it an excellent option for functional parts that need to bend without breaking.

- Ease of Use PETG is easy to print, similar to PLA. It has good layer adhesion and experiences less warping, making it accessible for both beginners and professionals. It doesn’t require an enclosed 3D printer or high-temperature heated bed, making it convenient for use on desktop 3D printers.

- Chemical and Water Resistance PETG offers excellent resistance to chemicals, making it suitable for applications that come into contact with harsh substances or liquids. Its water resistance also makes it an ideal choice for outdoor projects or items exposed to humid environments.

- Transparency PETG can be printed in transparent form, making it perfect for applications requiring clear or semi-transparent components, such as light covers, display cases, or protective enclosures.

Best Applications for PETG in 3D Printing Thanks to its combination of strength, flexibility, and resistance to moisture and chemicals, PETG is well-suited for a variety of use cases. Here are some common applications where PETG excels:

- Functional Prototypes PETG is great for functional prototypes that require strength and flexibility. It can endure mechanical stress, making it ideal for prototypes tested under real-world conditions.

- Outdoor and Waterproof Products With its resistance to water and UV rays, PETG is an excellent material for outdoor products like garden tools, fixtures, or protective covers. Its waterproof nature ensures long-lasting performance when exposed to moisture.

- Medical and Food Containers PETG is both chemically resistant and food-safe, making it suitable for medical containers, food storage products, and drink bottles. Its non-toxic properties make it ideal for applications where hygiene is critical.

- Wearable Items For wearable items like accessories, medical braces, or custom jewelry, PETG offers a balance between rigidity and flexibility. Its smooth finish and ability to withstand repeated movement make it perfect for functional wearables.

- Engineering Components PETG’s strength makes it a top choice for functional engineering parts. It can withstand mechanical stress, making it suitable for machine components, gears, and electronics housings.

How to Print Successfully with PETG While PETG is relatively easy to print, there are a few important factors to consider for optimal results:

- Extrusion Temperature PETG prints at a higher temperature than PLA, with an optimal range between 220°C and 250°C. Always check the manufacturer’s guidelines for the specific filament you’re using.

- Bed Temperature A heated bed is recommended for printing with PETG. Setting the bed temperature between 70°C and 90°C improves adhesion and minimizes warping.

- Print Speed PETG performs best at slower print speeds, usually between 30mm/s and 50mm/s. Printing too quickly can cause poor layer adhesion, so adjusting speed based on the complexity of your project is essential.

- Layer Adhesion PETG has excellent layer adhesion, but over-extrusion can lead to stringing or blobs. Properly calibrating your extruder and slowing down print speed can prevent these issues.

- Post-Processing PETG requires minimal post-processing. However, light sanding or polishing can enhance the surface finish for a more refined look.

Is PETG Right for Your 3D Printing Project? If you need a material that combines strength, flexibility, and chemical resistance, PETG is an excellent choice. It’s ideal for functional parts, outdoor projects, and engineering components. Its resistance to moisture, heat, and chemicals makes it a versatile material used across various industries, from medical to automotive and consumer goods. At Monk 3D Technologies, we offer premium PETG filament in a range of colors and diameters to meet your 3D printing needs. Whether you’re working on prototypes, functional parts, or final products, PETG provides a reliable and versatile solution for all your printing requirements.